Shot peening is a cold working process that may produce effective shape changes to the workpiece. Each type of cold working process introduces residual stresses during the forming of metal workpieces. The shape change has two factors: plastic deformation and elastic deformation. This is different from the hot working process, the residual stress will be eliminated in the self-annealing process, so there is only plastic deformation. The elastic deformation is due to the residual stress imposed on the workpiece during the cold working process.

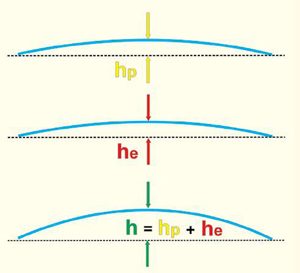

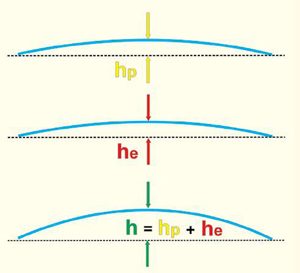

This factor makes the flat test piece bend. The plastic deformation hp and the elastic deformation he (residual stress) work together to produce the overall deformation h. Therefore, hp+he=h.

Figure 1. The combined action of plastic deformation hp and elastic deformation he causes Almen test piece deformation

Elasticity is not permanent, because it can be removed by stress relief. A common example is the Almen test piece after shot peening. When the stress is relieved, its bending will be reduced, and only plastic deformation will exist.

Analyzing the deformation caused by shot peening is very complicated , Including the simultaneous action of plasticity and elasticity theory. The simplified method calls the two theories separately as shown in this article.

The shape change of the workpiece is usually caused by shot blasting of. This deformation may be favorable, unfavorable, or too small to be ignored. Favorable shot peening deformation can be summarized as "shot peening" or "distortion correction", whereas unfavorable deformation can be summarized as "distortion".

The most common shot peening deformation is the Almen test piece. One side of the test piece was shot peened, so that its shape changed from a flat rectangular shape to a double curved shape. This is a favorable deformation, because the arc height when the test piece bends induced by shot peening is a parameter required for testing the strength of shot peening. As we all know, the shape change can be characterized by two mutually perpendicular curves. Plastic theory predicts this change in shape. The elasticity theory predicts the magnitude of the induced bending of the beam. This shape change is like the shape change caused by the "equivalent bending moment". In fact: the introduction of bending by shot peening is equivalent to applying an external bending moment. This external bending moment is also equivalent to the bending moment introduced by shot peening.

Chinese

Chinese