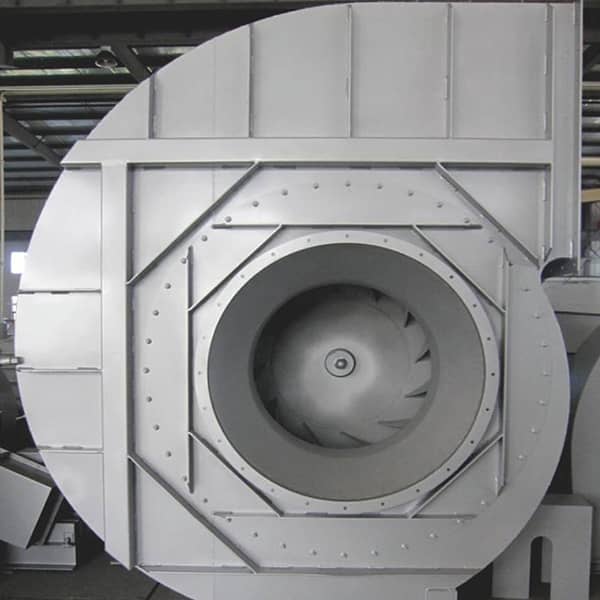

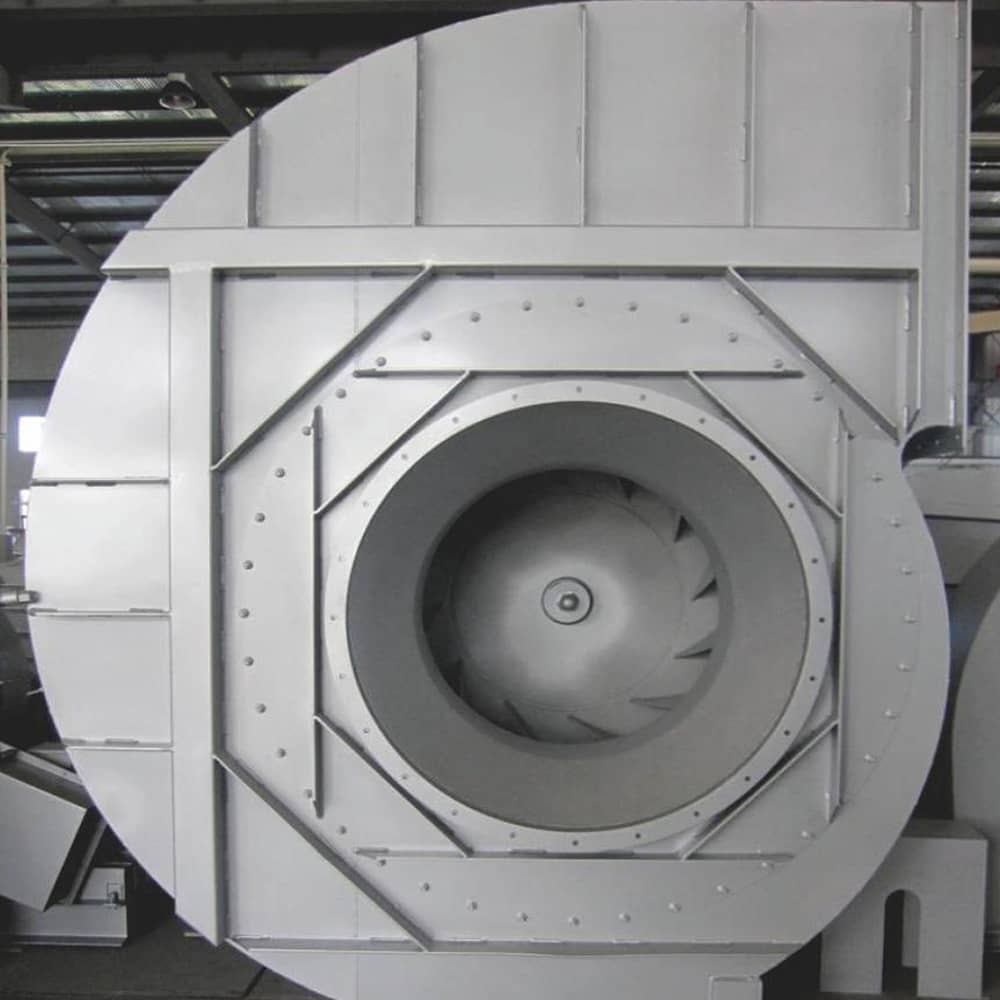

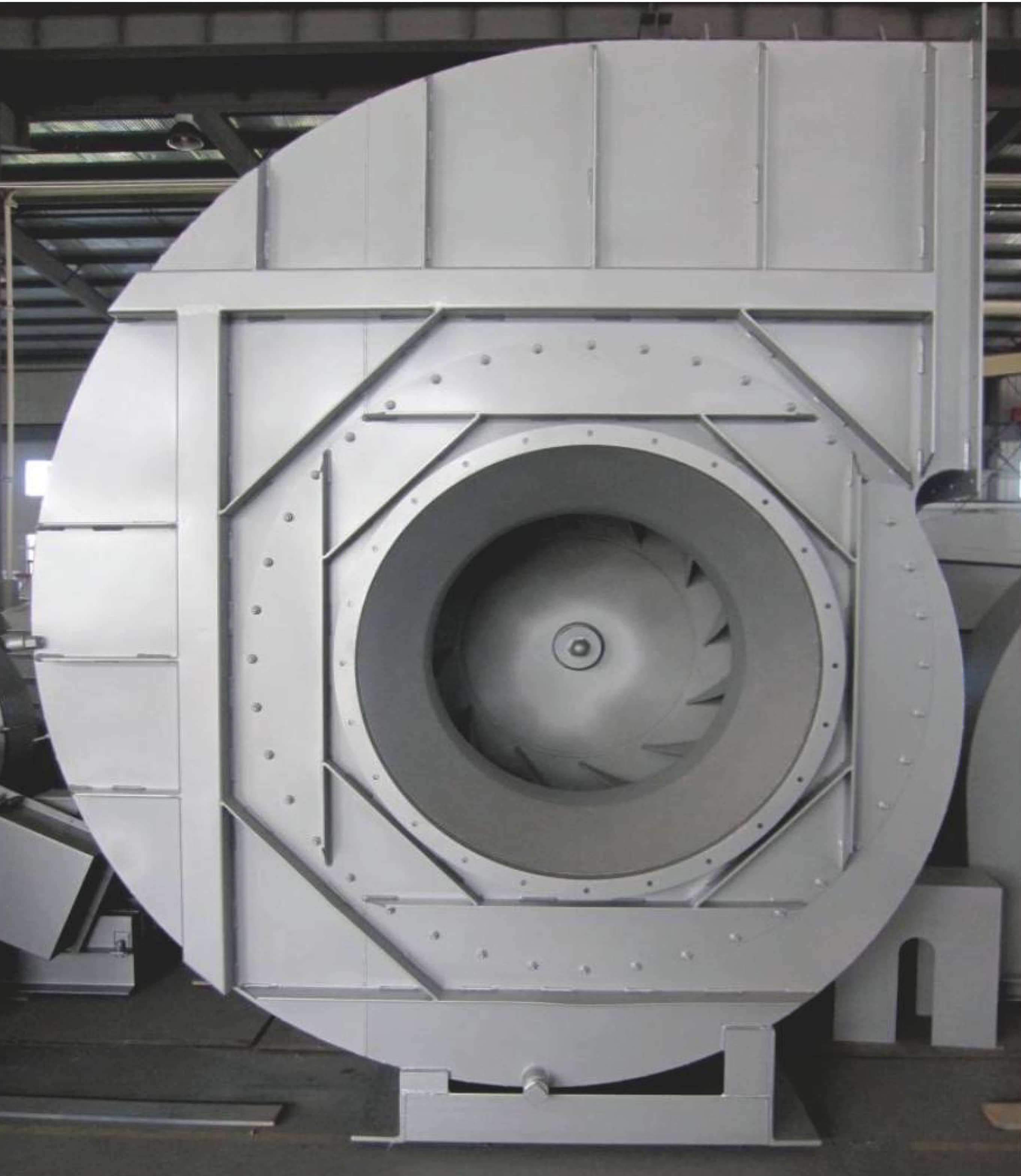

Fan housing

Our fan racks, shells, and air inlets are all monitored, which realizes the controllability of product quality and product delivery; at the same time, special process design and double-sided welding are adopted according to different places of use.

[Accessories]: Air inlet net cover, silencer, CIP nozzle, import and export compensator, shock absorber, cooling plate, air valve

Detection and correction

Executive standards for the vibration of the Rosenberg fan machine:

I SO 14694: 2003 and ISO 10816-3: 1998 group1

The whole machine vibration ≤ 2.5mm/s

Test equipment:

Imported Virbometer vibration detection software

American NI9234+9216 data collector

American CTCAC115-1 D three-axis vibration sensor

CEM AT-6 tachometer

Detection software:

Virbrometer is a powerful and extremely high-precision fan motor balance calibration software; it can be adapted to various single- and double-sided balance calibration mechanical equipment. The Vibrometer motorized balance test and calibration equipment is composed of Swedish test core software, NI data acquisition card, three-coordinate vibration sensor, and tachometer.

Pros:

The vibration of the whole machine is ≤ 2.5mm/s, the service life of the fan (especially the bearing) is delayed, the noise is reduced, and the fan is more energy-saving.

Fan wind parameter measurement:

Sweden machine balance calibration software combined with National Instruments data collector can ensure that the wind power balance reaches within 3mm/s.

Imported complete machine vibration testing equipment can simultaneously detect A-H-V three-dimensional vibrations and accurately calculate the balance compensation amount. This makes our fan complete machine balance level higher than the national standard, and the fan service life is significantly prolonged.

All the fans we produce must pass wind data testing to meet "GB10178-2006" and design standards.

Impeller balance correction:

Impeller balancing is an indispensable part of the fan production process. We use a well-known manufacturer's dynamic balancing machine with a balance accuracy of 0.5 g.mm/kg. The impeller is 100% tested according to the 1S01940 standard, and the impeller test is recorded and tracked.

Customer case

Thank you for choosing Paiting Technology's products! In addition to providing you with high-quality products, we pay more attention to sincere and good service. To build the best brand in the industry is the corporate purpose of Paiting. Service is the cornerstone of the brand. Therefore, we will create a continuous, efficient, advanced and complete service system. It is the permanent operating policy of Paiting Technology.

Patient Technology's three-stage service plan for users:

[Pre-sales]: According to user needs, provide professional pre-sale technical consultation for each user, help users analyze needs and process conditions; design and select the most ideal for users Equipment and process solutions;

[Sale]: Formulate the "Project Schedule" and "Memorandum of Sales Communication" to maintain a high degree of close communication with users on equipment technology, design, manufacturing and installation matters, and allow users to participate in the whole process And master real-time progress. Provide users with standardized and systematic professional technical training, popularize equipment and related process knowledge, conduct on-site operation demonstrations, provide maintenance common sense consultation, and provide one-stop services such as installation and commissioning;

[After-sales]: Establish equipment use, maintenance files and after-sales service communication groups for each user to keep abreast of the user’s use status; provide professional consulting services for product updates and functional improvements, with The professional after-sales service team regularly conducts return visits to new and old customers and equipment maintenance, and establishes equipment spare parts warehouses to meet the timely needs of users to replace parts during maintenance.

Chinese

Chinese