Application process

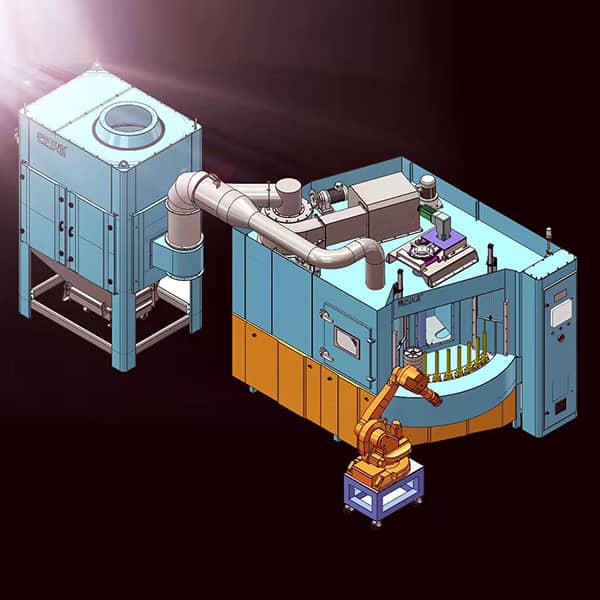

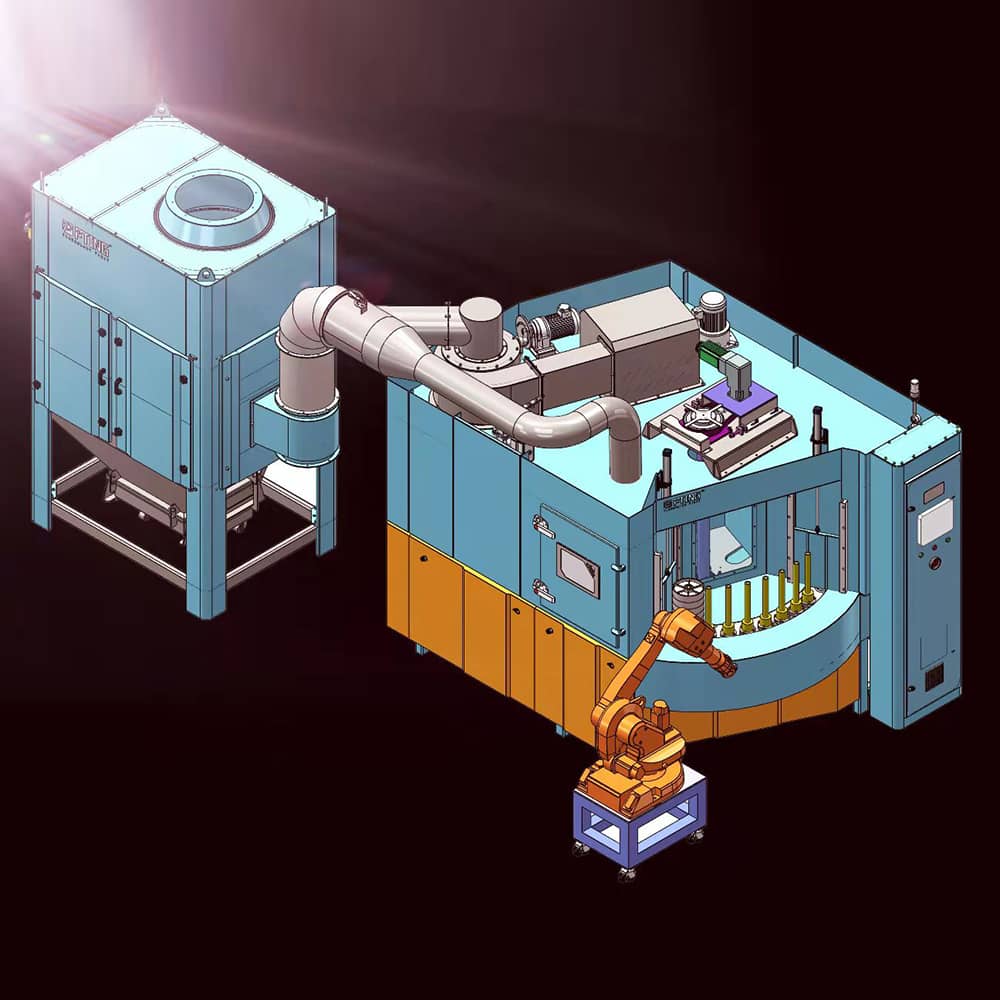

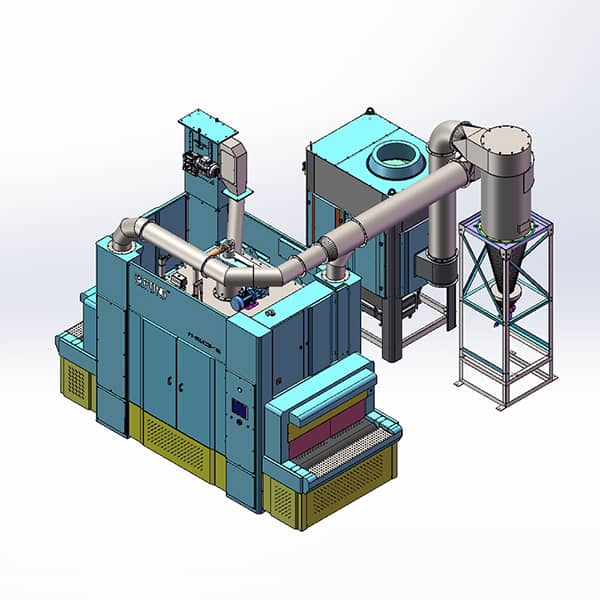

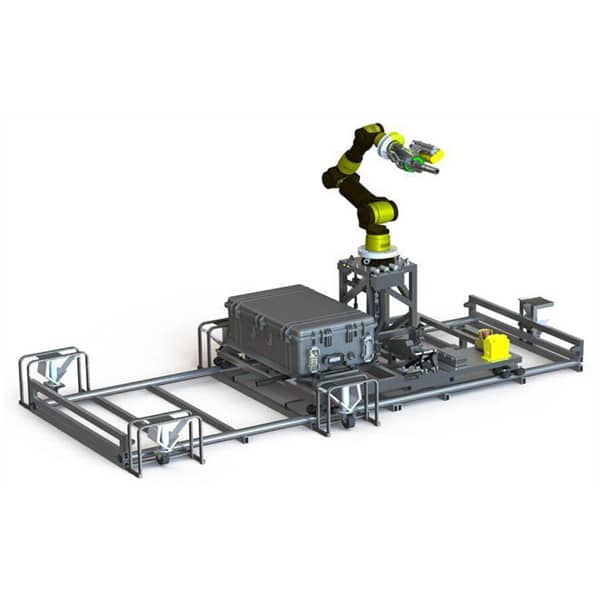

Suitable for flat workpieces: cookware, pots, aluminum plates, profile digital accessories, glass, auto parts, hardware, building materials, etc.

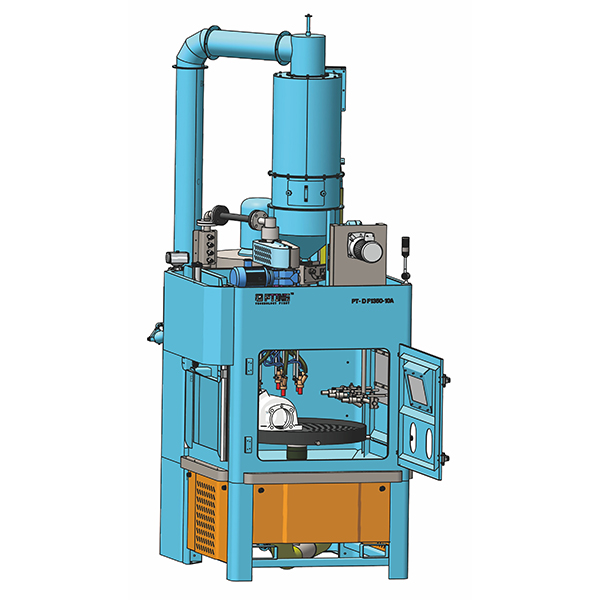

①. Pre-treatment of non-stick coating for cooking appliances: non-stick pans, soup pots, baking pans, bread molds, cake molds, pressure cookers, air fryer.

②. Surface pretreatment of household appliances: electric irons, heating plates, microwave ovens, ovens, dishwashers, sinks, sanitary hardware products.

③. Surface pretreatment of digital home appliances: mobile phones, computers, power banks, digital, electronic product housings, optical glass products.

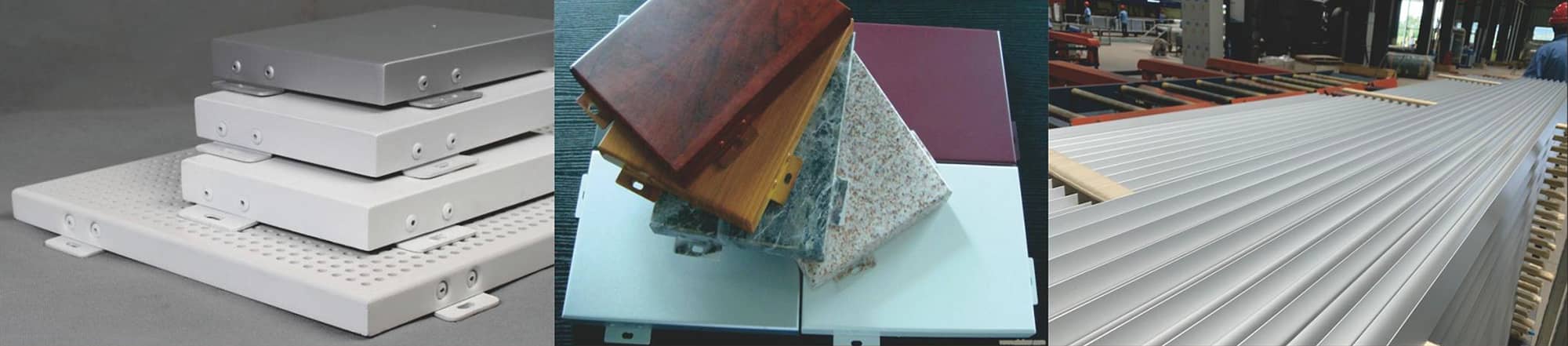

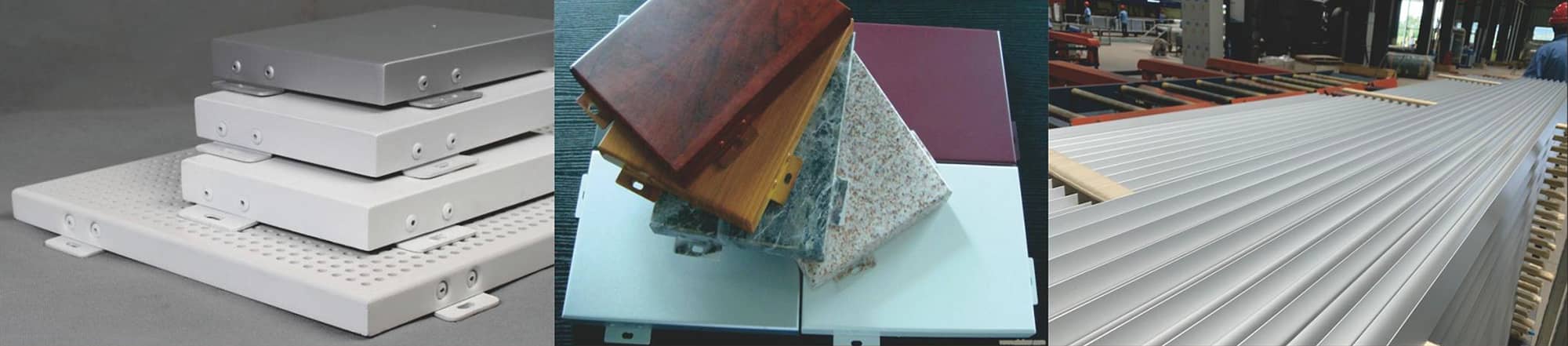

④. Surface pretreatment of building decoration materials: porcelain-fired aluminum panels, spray profiles, UV water-based paint solid wood furniture, stainless steel decorative profiles and plates.

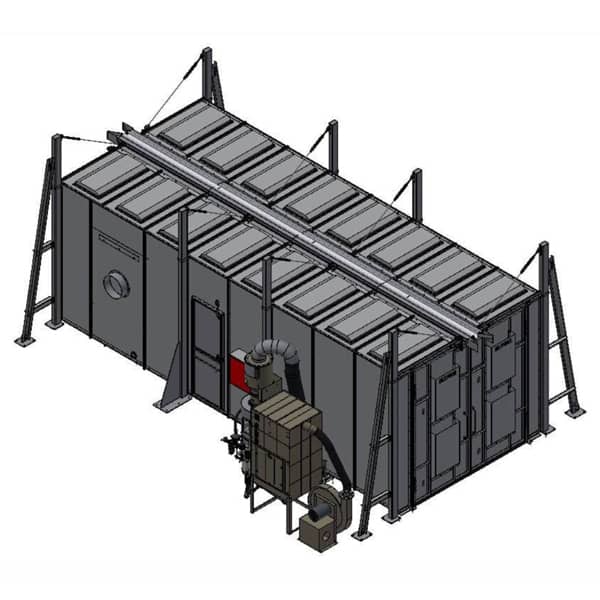

User site

Thank you for choosing Paiting Technology products! In addition to providing you with high-quality products, we pay more attention to sincere and good service. To build the best brand in the industry is the corporate purpose of Paiting. Service is the cornerstone of the brand. Therefore, to create a continuous, efficient, advanced and complete service system It is the permanent operating policy of Paiting Technology.

Patient Technology's three-stage service plan for users:

[Pre-sales]: According to the needs of users, provide professional pre-sale technical consultation for each user to help users analyze their needs and process conditions; Users design and select the most ideal equipment and process solutions;

[Sale]: Develop the "Project Schedule" and "Sale Communication Memorandum" to maintain a high degree of closeness with users on equipment technology, design, manufacturing and installation matters The communication allows users to participate in the whole process and master real-time progress. Provide users with standardized and systematic professional technical training, popularize equipment and related process knowledge, conduct on-site operation demonstrations, provide maintenance common sense consultation, and provide one-stop services such as installation and commissioning;

[After-sales]: Establish equipment use, maintenance files and after-sales service communication groups for each user to keep abreast of the user’s use status; provide product updates and functions Improved professional consulting services, equipped with professional after-sales service teams, regular return visits to new and old customers and equipment maintenance, and establishment of equipment spare parts warehouses to meet the timely needs of users to replace parts during maintenance.

Chinese

Chinese