Sandblasting (shot) process:

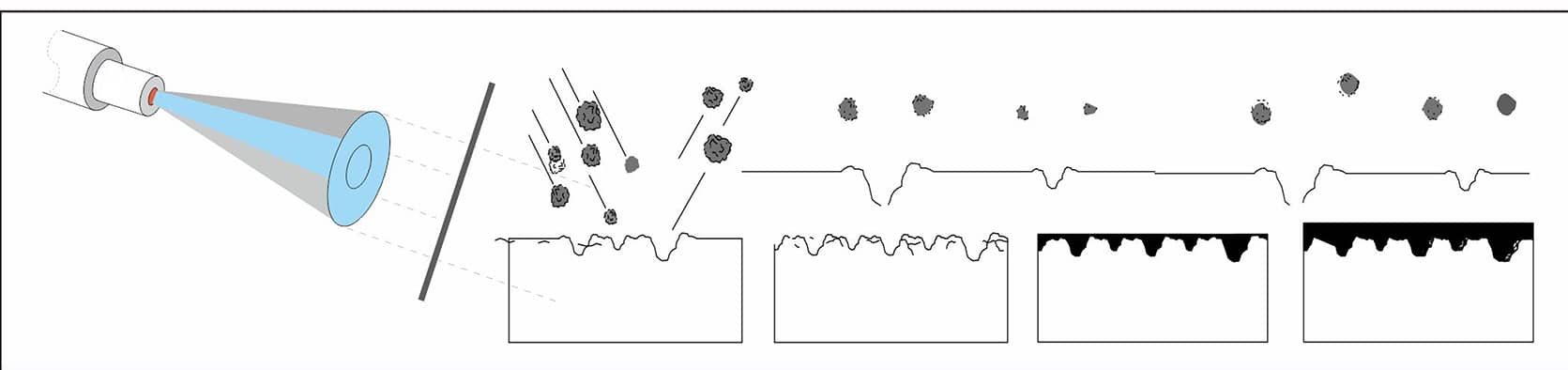

Sandblasting (shot) is a mechanical surface pretreatment method that uses the impact of high-speed sand flow to clean and roughen the surface of the substrate. Compressed air is used as the power to form a high-speed jet beam to spray abrasives (emery sand, iron sand, stainless steel sand or abrasives of various shapes and materials) on the surface of the workpiece at high speed, so that the outer surface shape of the workpiece surface is changed, and the surface of the workpiece is affected by the abrasive. The impact, cutting and grinding of the workpiece can obtain a certain degree of cleanliness and different roughness on the surface of the workpiece, increase the surface area of the workpiece, and improve the mechanical properties of the workpiece surface. At the same time, it also improves the fatigue resistance of the workpiece and increases the workpiece. The adhesion between the post-treatment coatings extends the durability of the coating film, and is also conducive to the leveling of the coating and the improvement of the decorative effect.

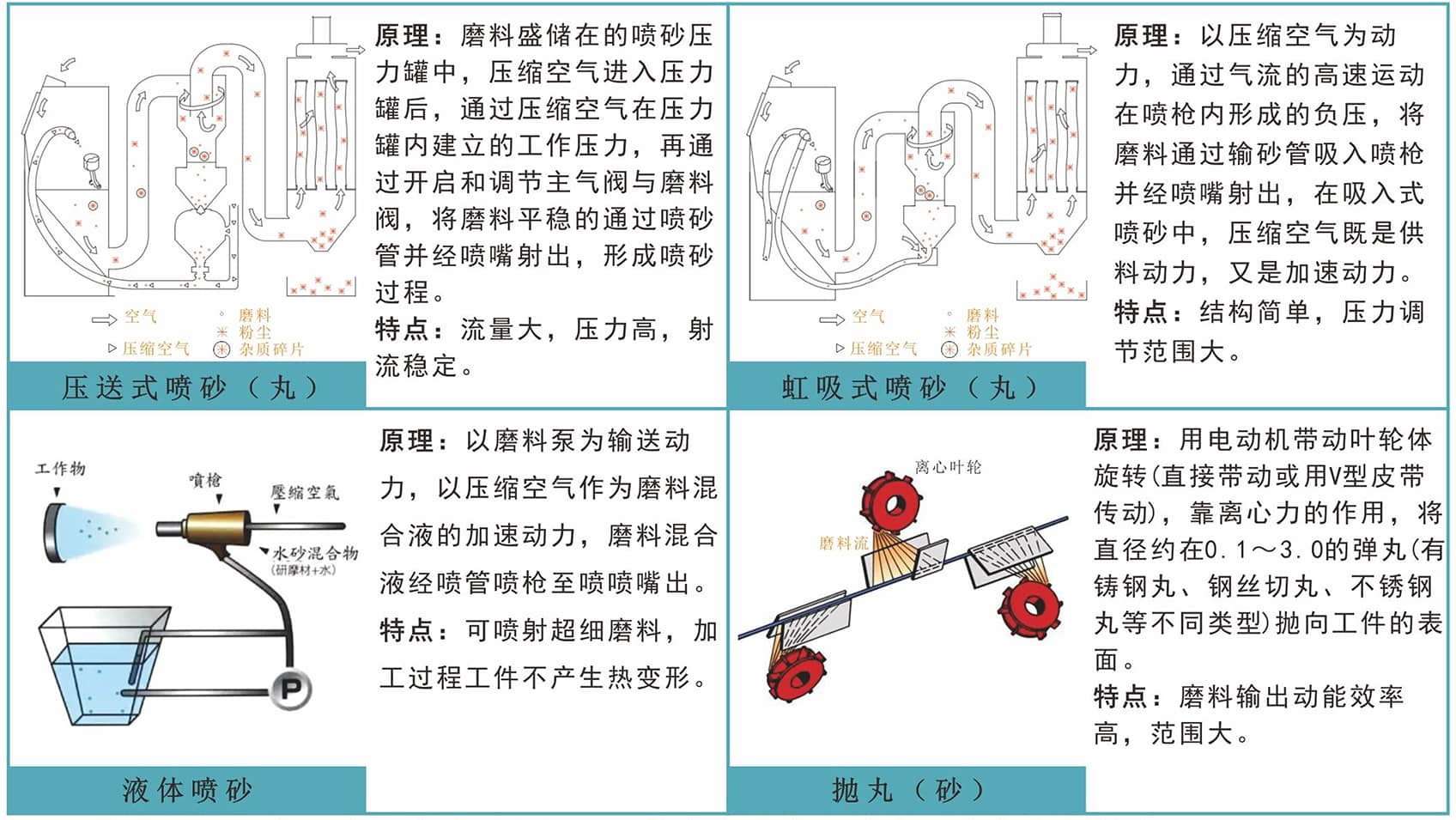

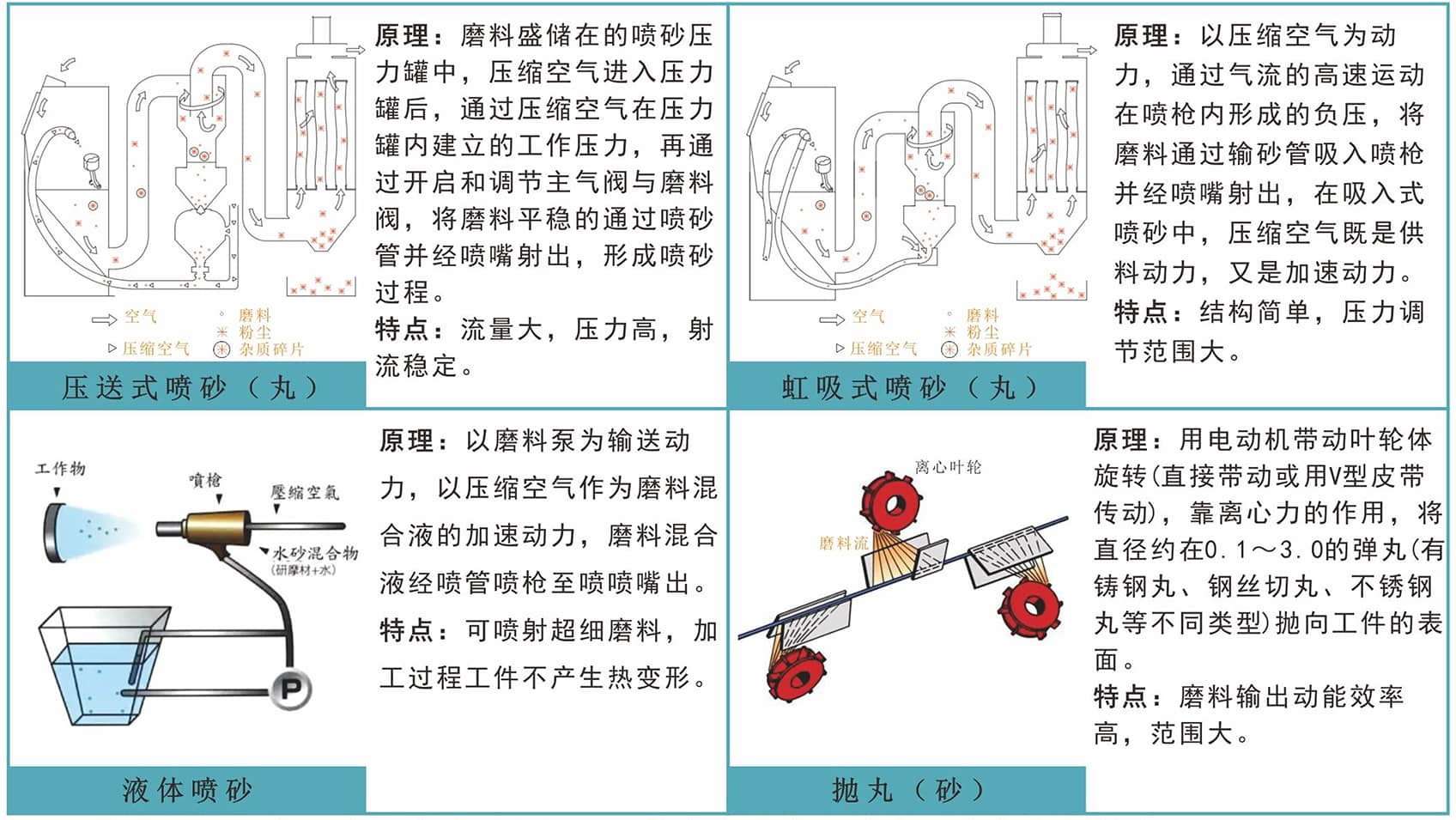

Basic principles of mechanical surface pretreatment-sand blasting (shot) and shot blasting:

※Pressure-feeding, siphoning, and liquid blasting (pills) use compressed air as the main power to generate abrasive jets.

※In shot blasting, the motor drives the blades to generate centrifugal power to generate abrasive beams.

Purpose of sandblasting (shot) and shot blasting:

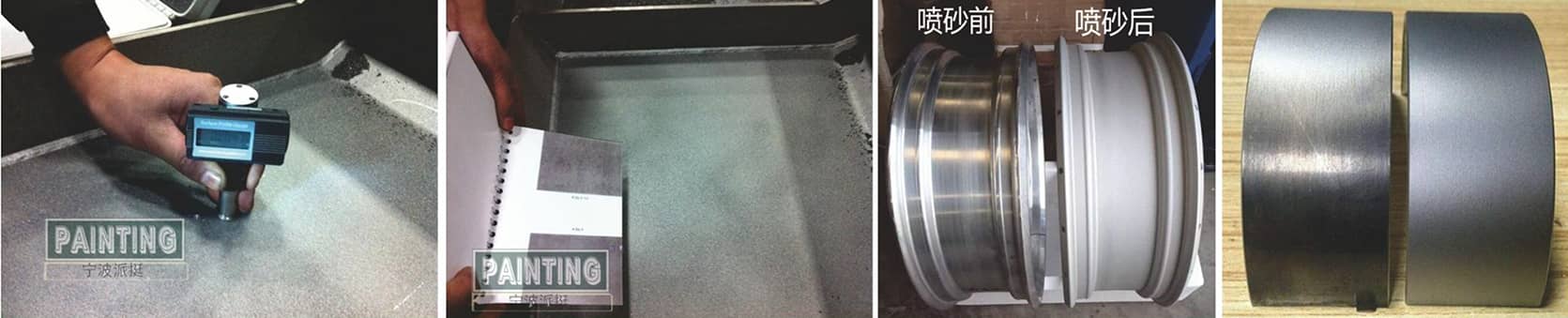

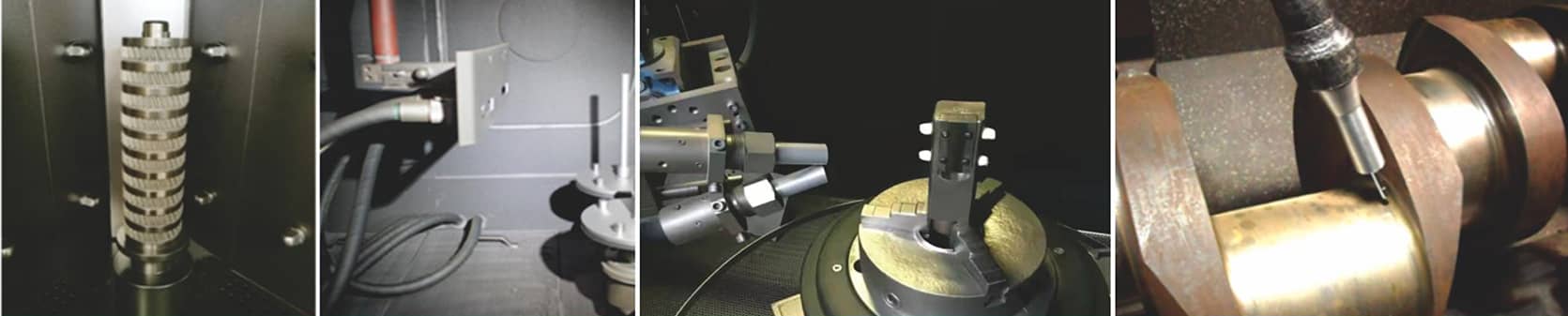

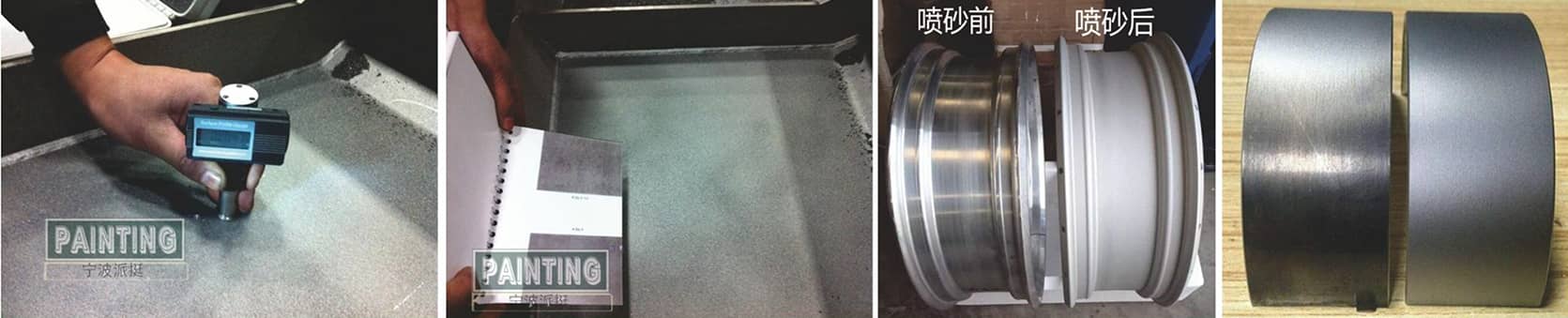

1. Roughness on the surface of the workpiece: the surface of the workpiece will have different values of roughness Ra due to different abrasive grain sizes, and the surface area will increase. The value of Ra can be obtained by measuring with a roughness meter.

2. Make the surface of the workpiece clean: remove impurities, rust, oil slick, oxide skin, burrs, etc. on the surface of the workpiece. The cleaning level is: $2 1-3 level to obtain the level value through the 1$08501-3 standard comparison picture.

The above 2 process results roughness Ra cleanliness Sa

The main service is for workpiece coating (spraying or electroplating, etc.), process requirements for pretreatment adhesion before gluing, or surface decoration requirements for workpieces.

3. Shot peening: shot peening of crankshafts, aerospace gears, springs and other parts is a special cold processing process, which continuously impacts the surface of the metal material through the flow of projectiles and makes the surface (0. 1~0. 8mm) material Cyclic plastic deformation occurs, thereby forming a process of deformation strengthening. Through the cyclic plastic deformation of shot peening, the structure of the material is changed, the sub-grain is greatly refined, the dislocation density is increased, and the lattice distortion is increased; a high macroscopic stress is formed, and the surface roughness and surface morphology are also increased. Everything changes. Various changes in the surface of the material will significantly improve the fatigue and stress corrosion resistance of the material, and strengthen the surface performance of the material.

Factors affecting the effect of the sandblasting process:

1. Abrasives: divided into metallic abrasives and non-metallic abrasives. Different particle sizes, shapes, materials, and hardness will produce different shapes of roughness and cutting force. Different roughness values and cleanliness values;

2, air pressure and flow: the greater the pressure and flow, the higher the blasting efficiency and the more uniform;

3, the spray angle And distance: the best distance for suction jet is 150mm, the best distance for press-in jet is 300mm; the ideal angle is 45 degrees;

4. Spray method: press-in/siphon/. With the same air consumption and nozzle diameter, the efficiency of the press-in type is about twice that of the suction type.

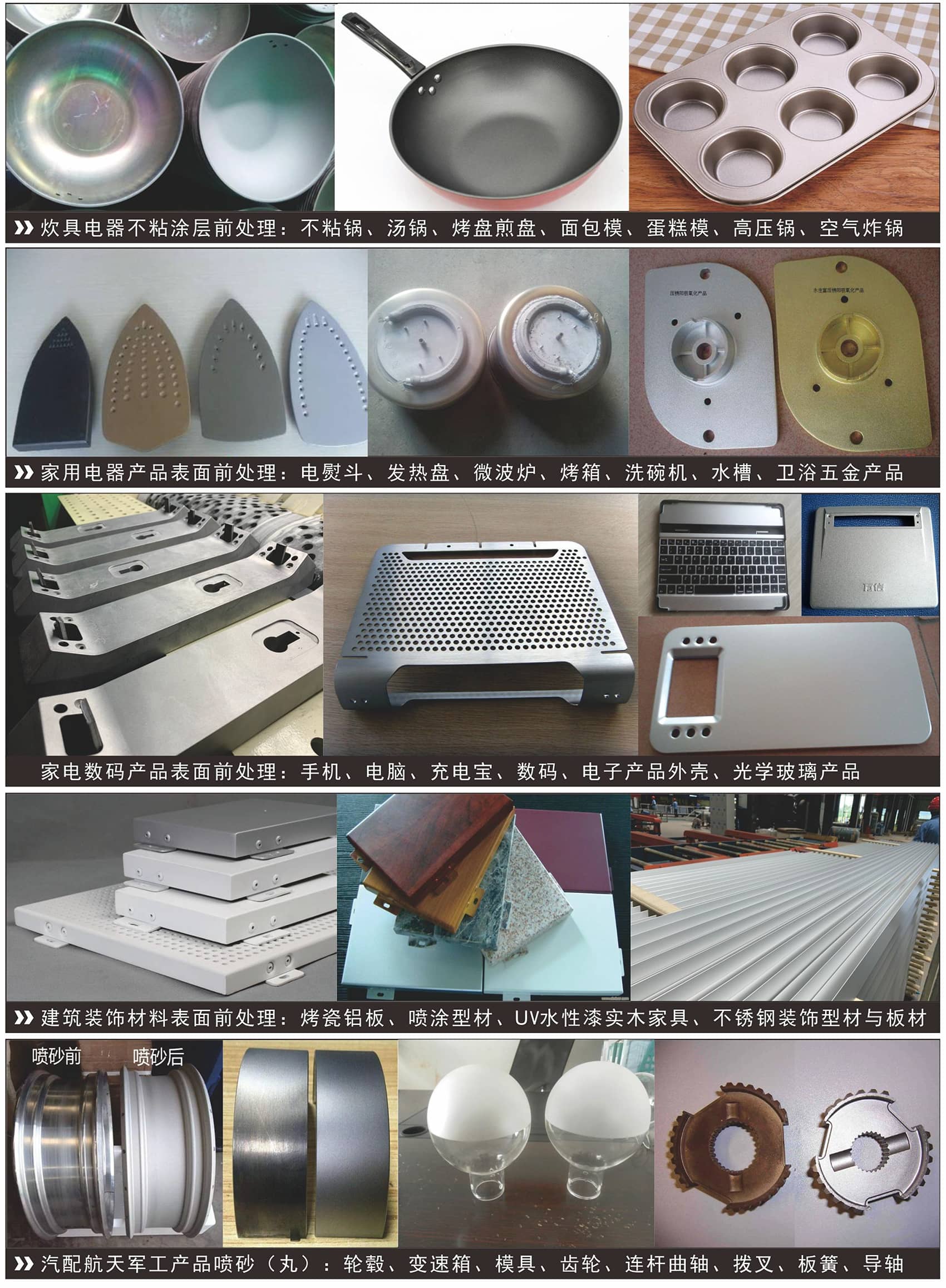

Light Industrial Products

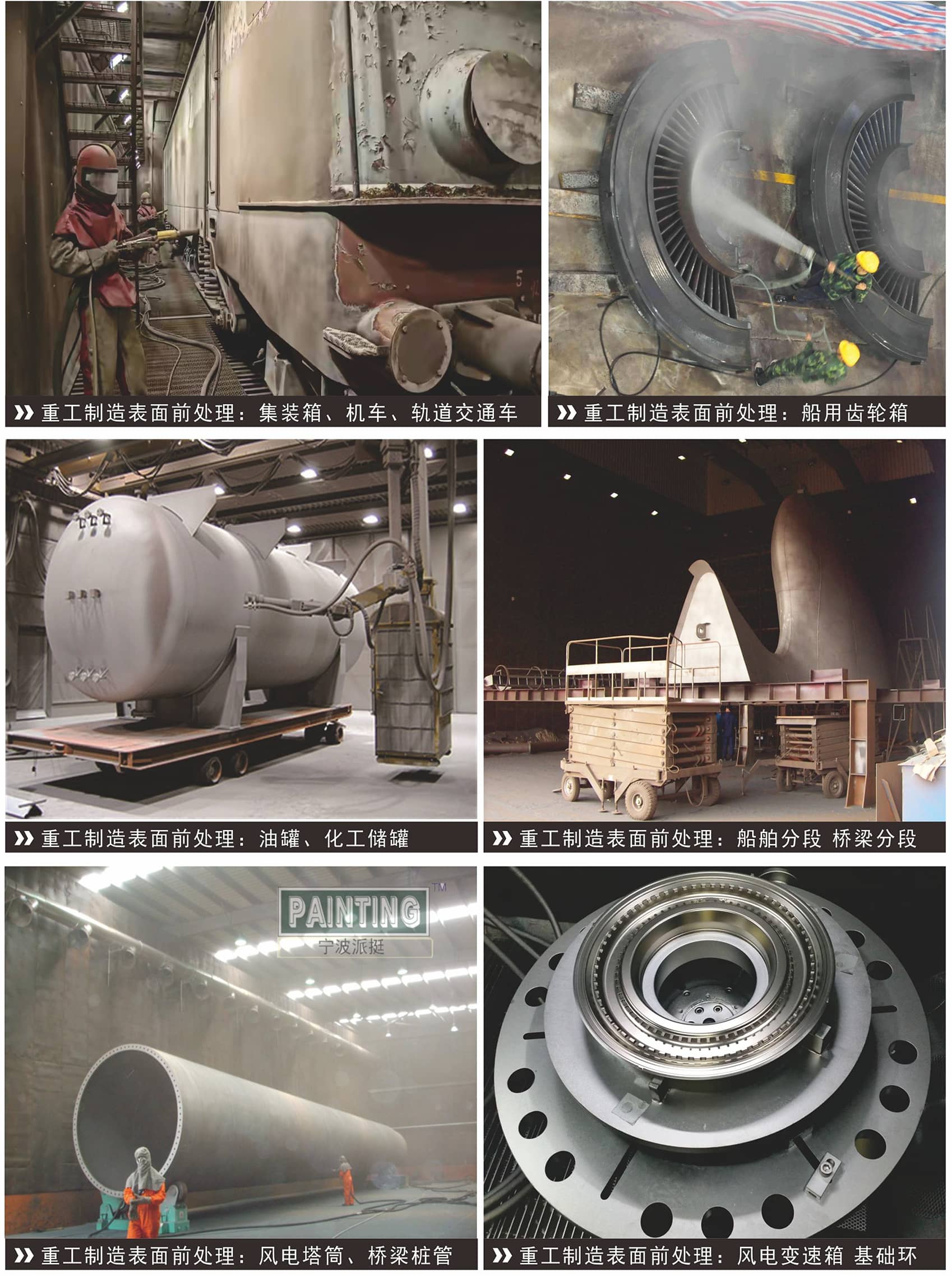

Heavy industry products

Chinese

Chinese