Not long ago, at the launch of the new iPhone series, the back cover of the mobile phone has adopted a new generation of ceramic bead blasted AG glass technology, which is delicate and moist to the touch. It has a thin, soft and comfortable feeling, and it also has the advantage that the glass material is not easy to be stained with fingerprints. With the advent of the 5G era, people have higher and higher requirements for the visual experience and aesthetics of mobile phones. The development of ceramic bead blasting AG glass technology has promoted the transformation of mobile phone back covers from traditional metal, plastic and other materials to AG glass. developing.

When it comes to frosted glass made by AG process, everyone should be familiar with it. At present, high-end mobile phone brands such as Apple, Huawei, OPPO, OnePlus, etc. are all using it. On the recently released iPhone 11 Pro series, Apple made the glass on the back of the fuselage into a matte texture through the AG process, bringing a better feel.

AG glass (Anti-Glareglass) is anti-glare glass, which refers to the special treatment of the glass surface by etching, coating, sandblasting or polishing, etc. Change the roughness of the glass surface, so that the surface has a matte effect and achieves the effect of diffuse reflection.

The AG implementation method of early mobile phone glass cover is mainly chemical etching, such as Huawei's Mate20, OPPOR17pro, OnePlus 6, etc. But Chemical etching is expensive and relatively environmentally friendly. It is understood that the glass shell of the new model released by Apple on September 11 adopts a new generation process developed in cooperation with processing manufacturers - ceramic bead sandblasting (not the AG etching mentioned earlier), and the glass back cover of the iPhone 11pro series is also Switched from a glossy finish to a custom matte texture.

Sandblasting

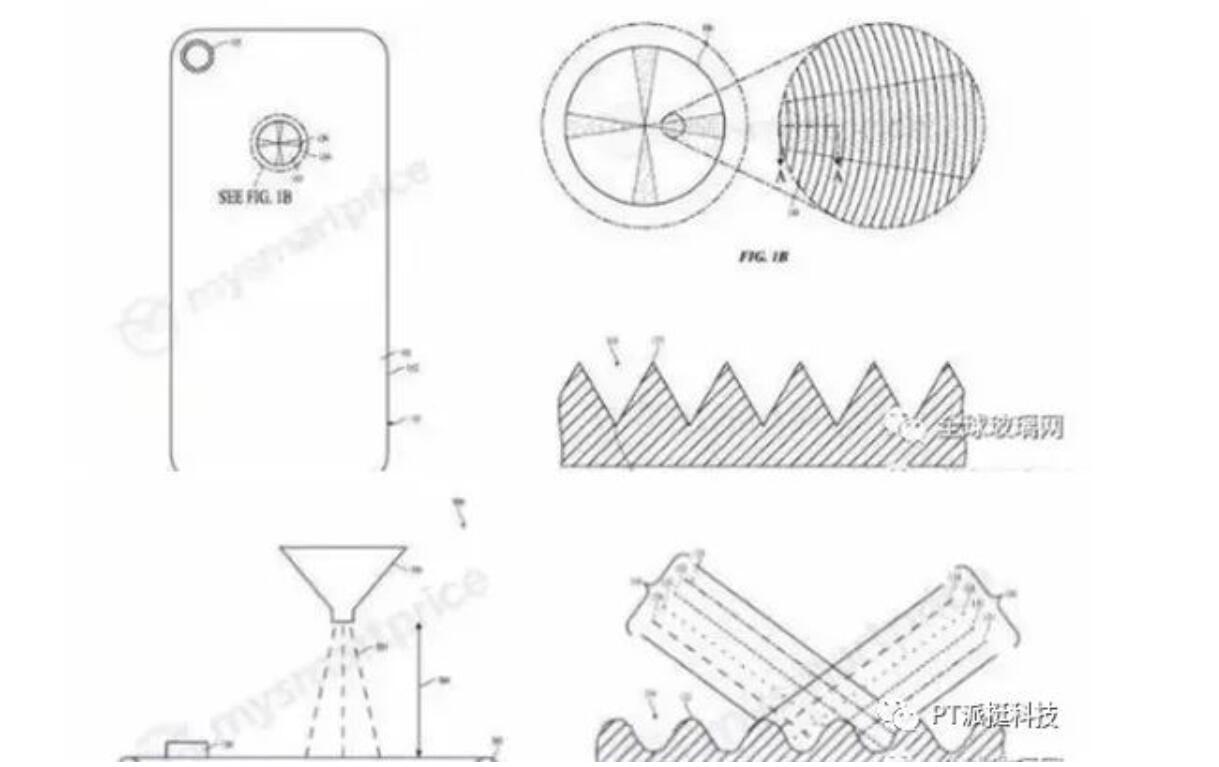

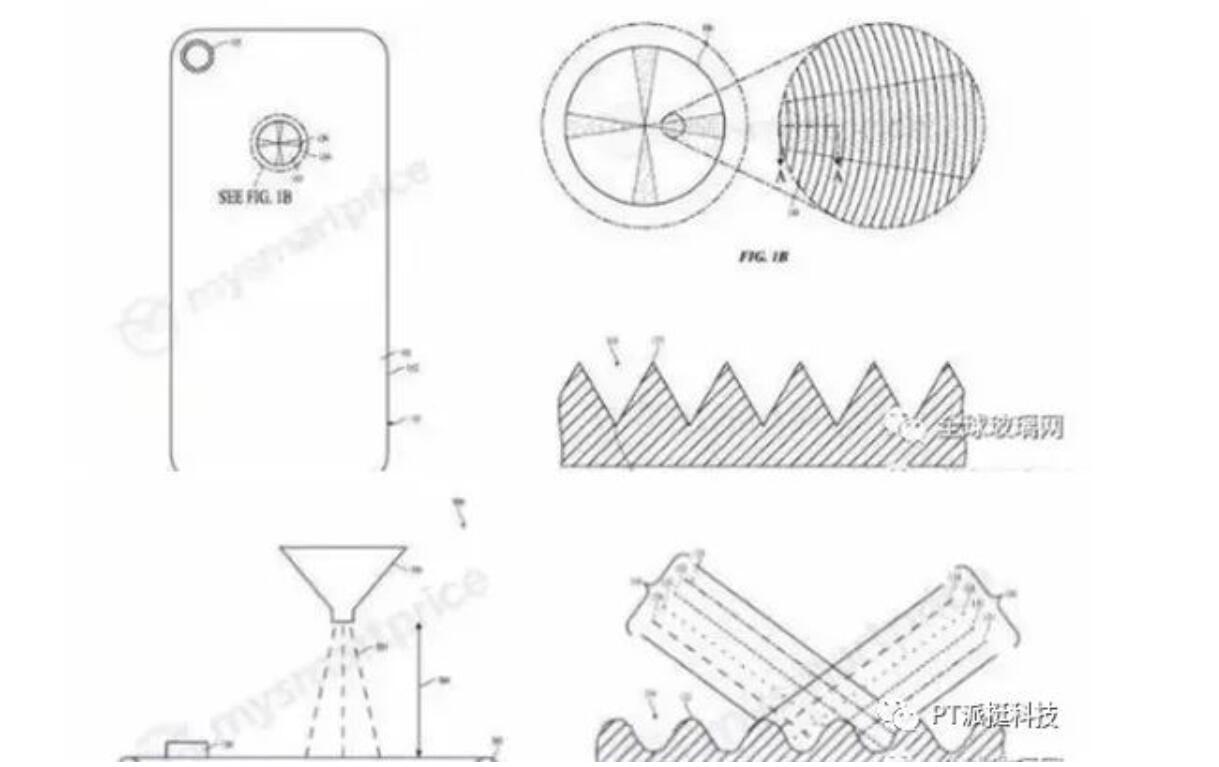

Sandblasting is a process in which a mixture of sand and water is used as a medium and is sprayed on the surface of the glass by the pressure generated by a sandblasting machine. As early as 2018, an Apple patent called SurfaceFinishing was exposed, which showed that Apple was developing a new iPhone body processing process.

The patent details the process, which involves sandblasting to create textured grooves in the body, although Apple uses ceramic beads instead of conventional sandblasting.

Sand blasting The impact of the sand particles sprayed by the sandblasting machine on the surface of the workpiece makes the surface of the workpiece obtain a certain The smoothness and different roughness and particle size of the workpiece are improved, and the mechanical properties of the workpiece surface are improved, thus improving the relief of fatigue, and also increasing the adhesion between the coating and the coating, prolonging the durability of the coating film, which is also conducive to The leveling and decoration of coatings can remove impurities, variegated colors and oxide layers on the surface, and at the same time roughen the surface of the medium, make the surface of the substrate residual stress and improve the hardness of the surface of the substrate. At present, many domestic enterprises have mature technology and equipment, which have been used in many well-known brand mobile phones.

The advantages of sandblasting are:

The process flow is simplified, the production efficiency is high, and it is more environmentally friendly. Sandblasting can be used in a wider range and can also be used on ceramic cover plates. It is understood that Apple's new generation of Applewatch also uses sandblasting. With the release of Apple iPhonepro matte AG glass, a new generation of AG glass is sandblasted. Processing may become the mainstream process for surface treatment of 5G mobile phone casings in the future.

With the advancement of technology, AG etching has become the mainstream technology of glass surface treatment Anti-blue light, can also be applied to the texture design of the glass surface.

Zhejiang Paine Technology is a leading supplier of surface treatment equipment in China. Provide professional process technology and sandblasting equipment for global users. Welcome to inquire!

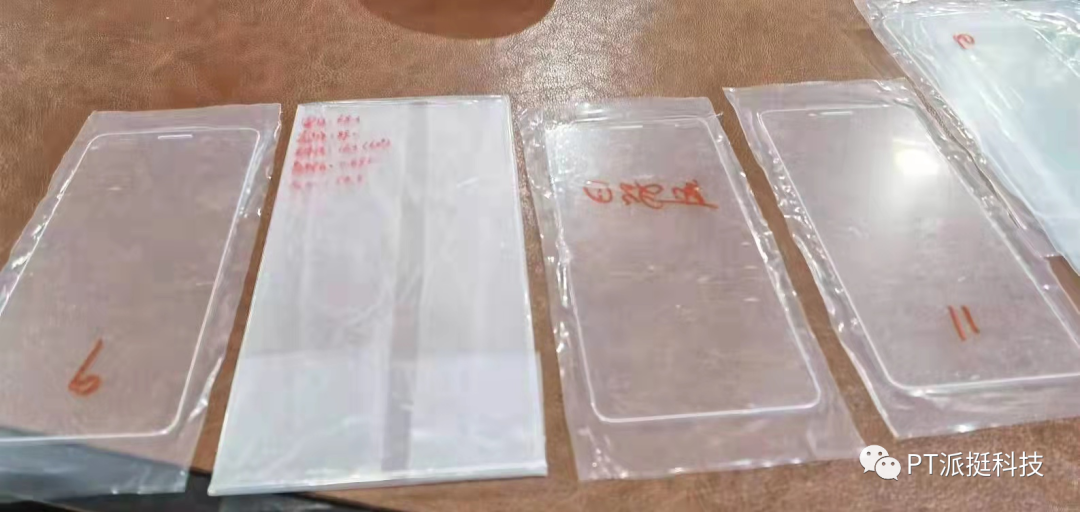

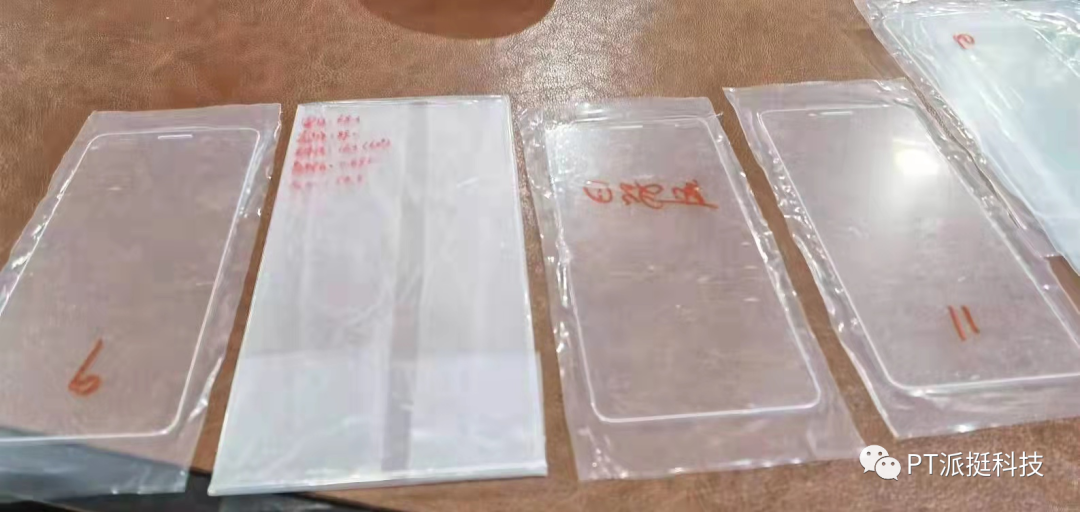

The AG sandblasted glass sample made by Pairing Technology for Apple supplier

Paine Technology AG special liquid sandblasting equipment for glass

Chinese

Chinese