1. Sand blasting equipment has poor stability, uneven sand blasting and low productivity;

2. Sand blasting equipment has large energy consumption, large sand material consumption and high cost;

3. The sandblasting equipment has poor environmental protection performance, the environmental protection discharge is not up to the standard, the production environment is bad, and operators are hard to find;

4. The compatibility of sand blasting equipment is poor, and heterogeneous plates cannot pass through the equipment.

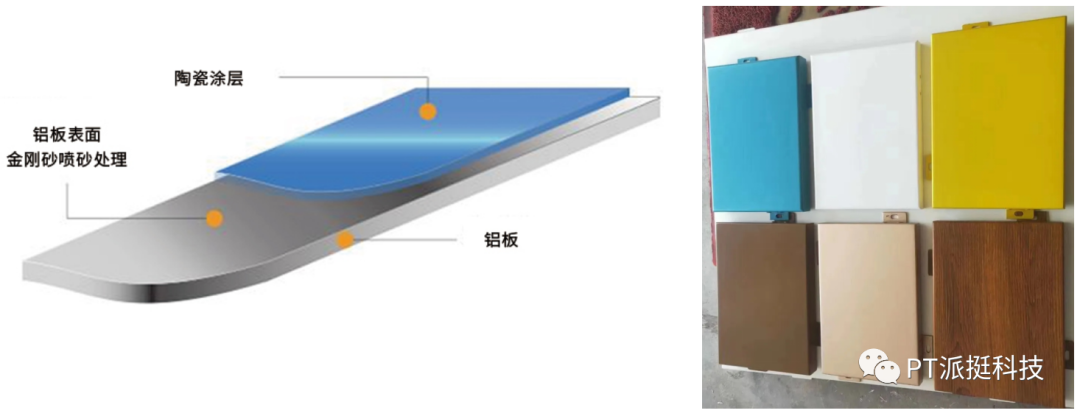

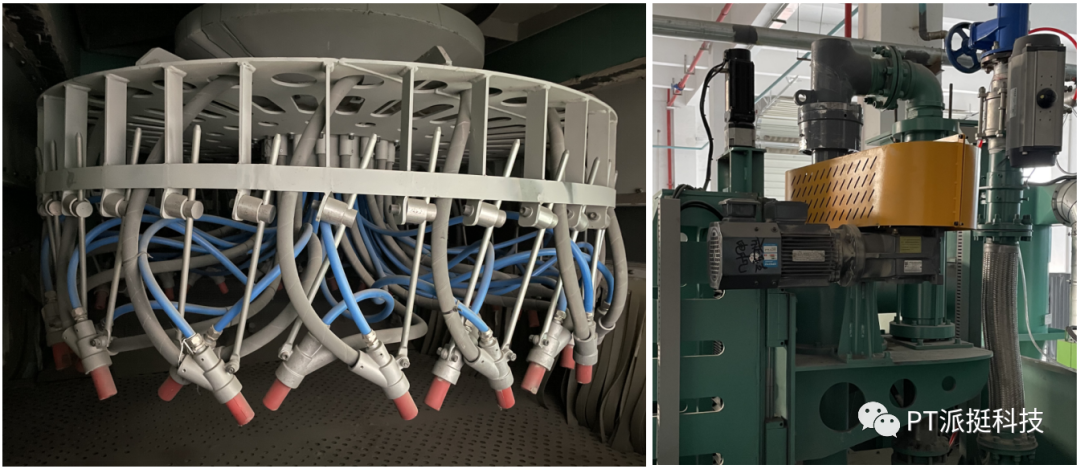

The special sandblasting machine for porcelain veneers jointly developed by Patting Technology and an aluminum veneer enterprise in Jiangsu for 3 years has comprehensively solved the above pain points and brought good news to the majority of aluminum veneer manufacturers:

1、 The technology of "rotary lifting spray gun module", which is the first in the world, perfectly solves the problem of uneven sand blasting with the traditional swing spray gun. At the same time, the compatibility range of the lifting spray gun module with the plate height reaches 10-400mm; The linear speed of aluminum plate sandblasting is up to 2.8-4M/min; Effective width up to 1600mm;2、 The technology of sedimentation type large air volume and low pressure dust remover+multi-stage cyclone separation and dust removal is adopted to solve the problem of dust overflow during sand blasting. At the same time, the particle size of abrasive separation can be finely adjusted to keep the surface roughness of the plate highly uniform. Save sand to the greatest extent.

Chinese

Chinese